- Home

- About us

- Products

- Monthly Jewelry Design

- 18k Gold Plated Earrings

- 18k Gold Plated Jewelry Sets

- S925 Silver Earrings

- 18k Gold Plated Bracelets & Bangle

- 18k Gold Plated Rings

- S925 Silver Necklace

- 18k Gold Plated Pendant Necklaces

- 18k Gold Plated Pendants

- S925 Silver Ring

- S925 Silver Jewelry Set

- Custom Jewelry

- Mother's Day Jewelry

- Valentine's Day Jewelry

- Christmas Jewelry

- Religious Jewelry

- Faqs

- News

- Certificate

- Contact us

-

-

-

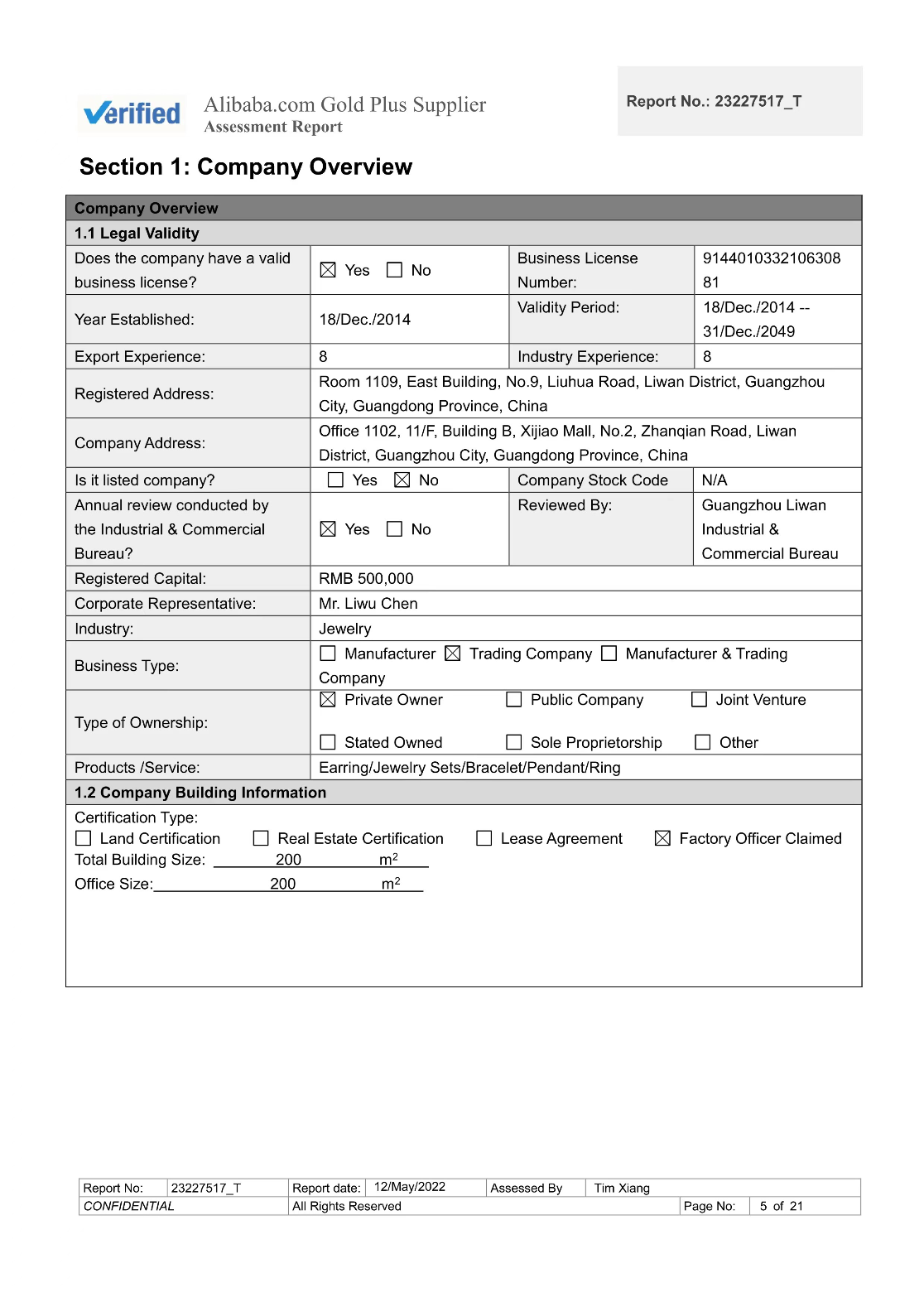

Certification

Issuing authority : SGS

Valid period : 2021/4/6 - 2022/5/6

Certicifation

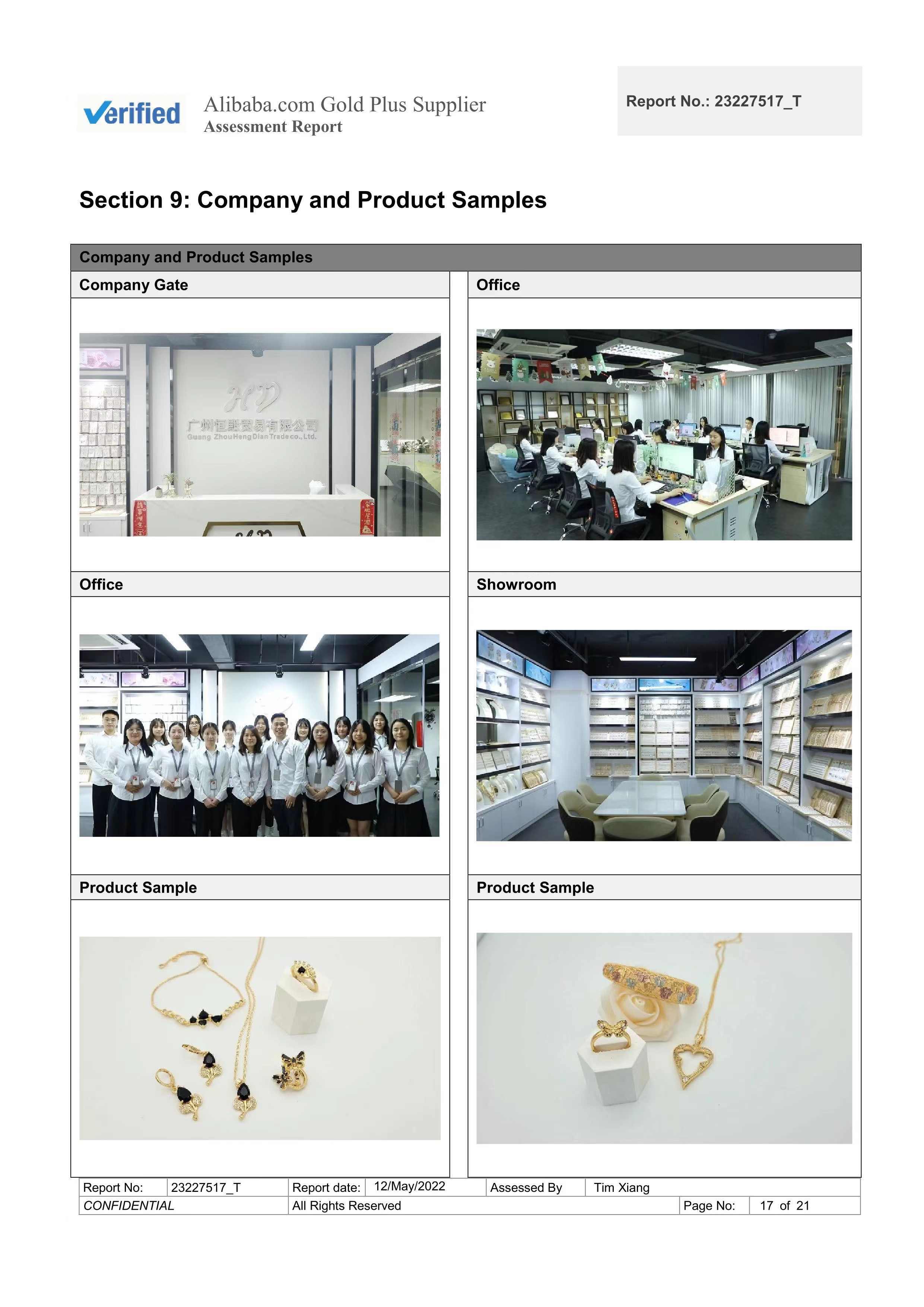

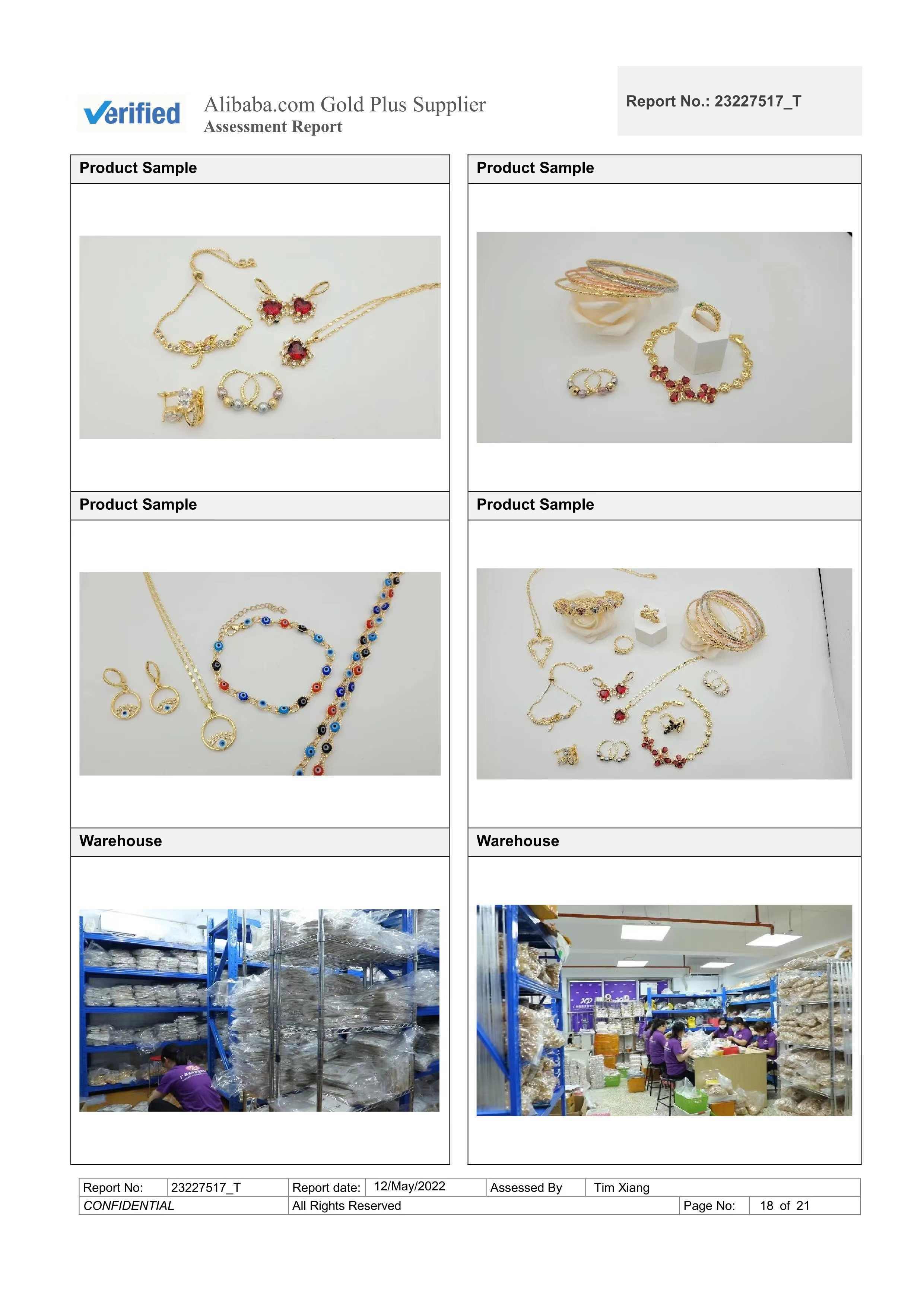

Guangzhou Heng Dian Trade Co., Ltd. is a gold supplier of jewelry on Alibaba.com, the reports you see are issued by authoritative institutions, you can rest assured in the choice of suppliers to cooperate with us, we will never let you down.Our main products are: women's earrings, jewelry sets, rings, bracelets, necklaces and so on, a variety of styles and follow the fashion trend, in the product style update, we have always been praised by customers! We have a stable supply chain and can meet your demand for shipping volume at the first time, of course, if you have a custom demand, we will also provide the corresponding custom service, customer first is always our purpose.We have 15 years of history of production factories and excellent business operations team, to provide you with a great experience of cooperation services. If you are looking for quality jewelry or quality jewelry suppliers, we warmly welcome you to open a friendly negotiation with us, Hengdeng is always by your side!

-

-

-

-

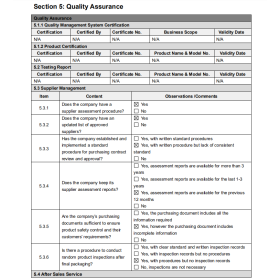

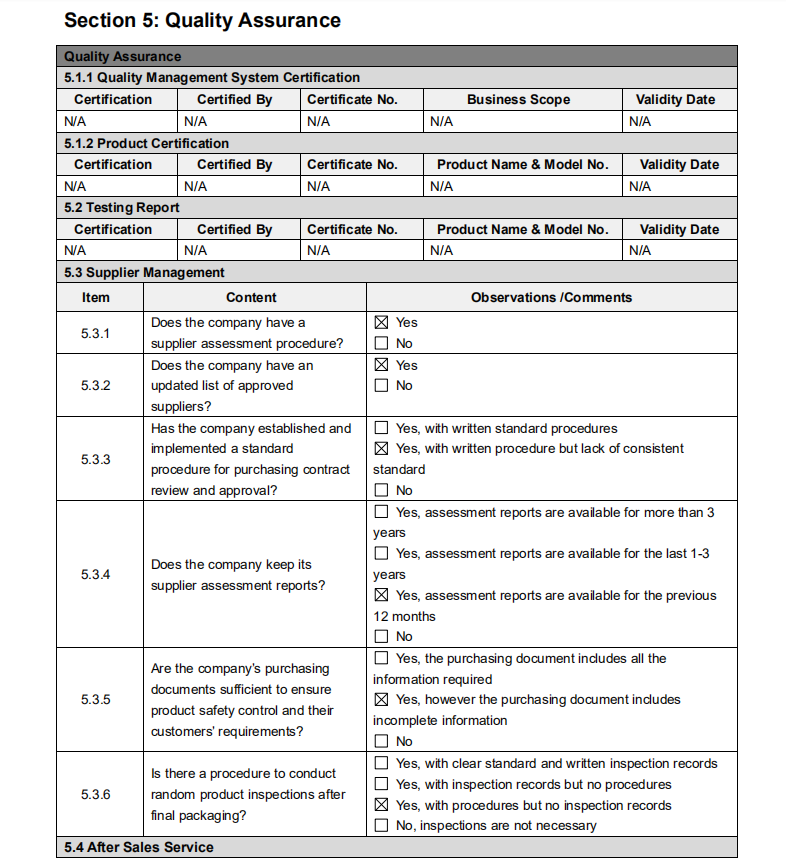

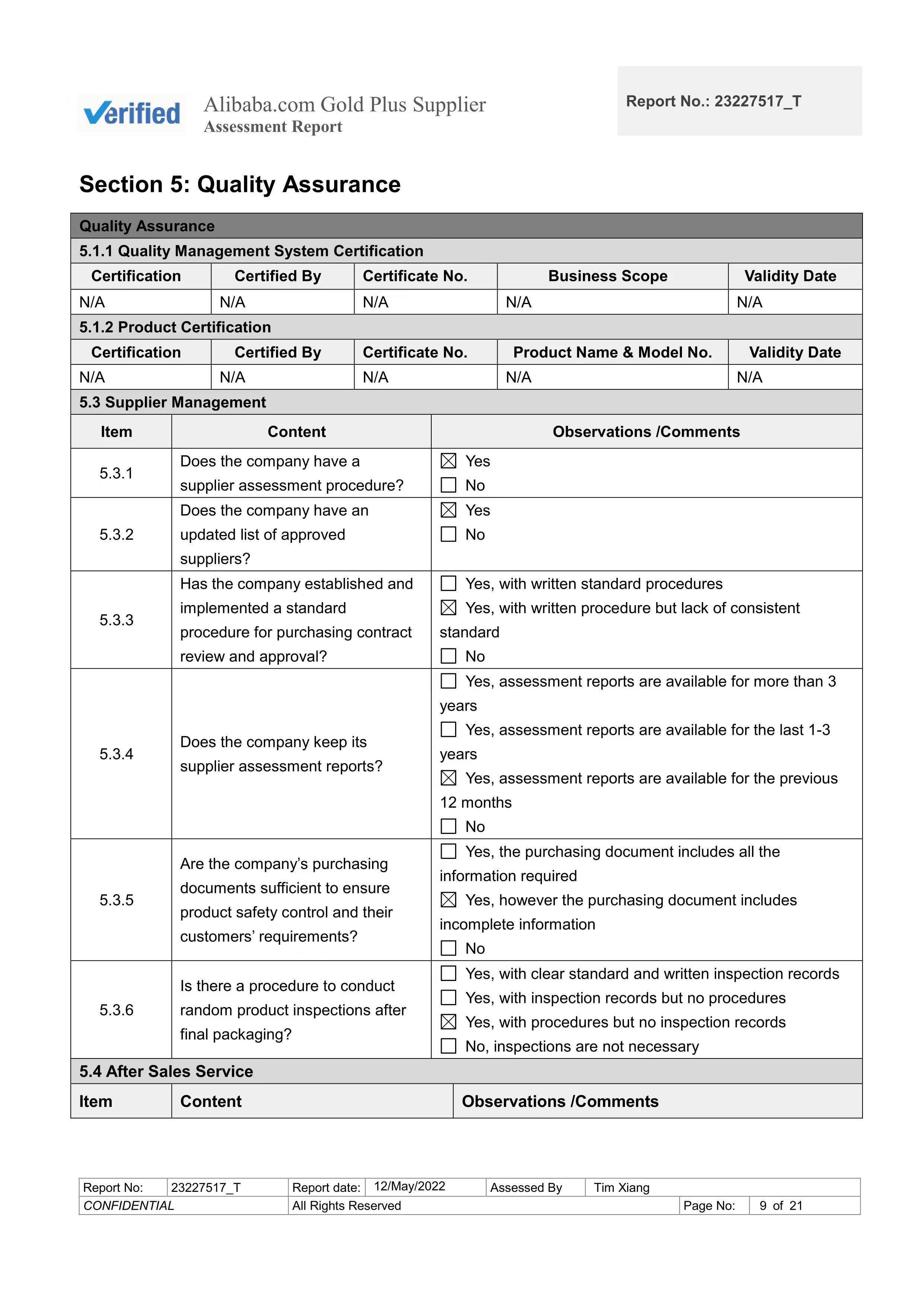

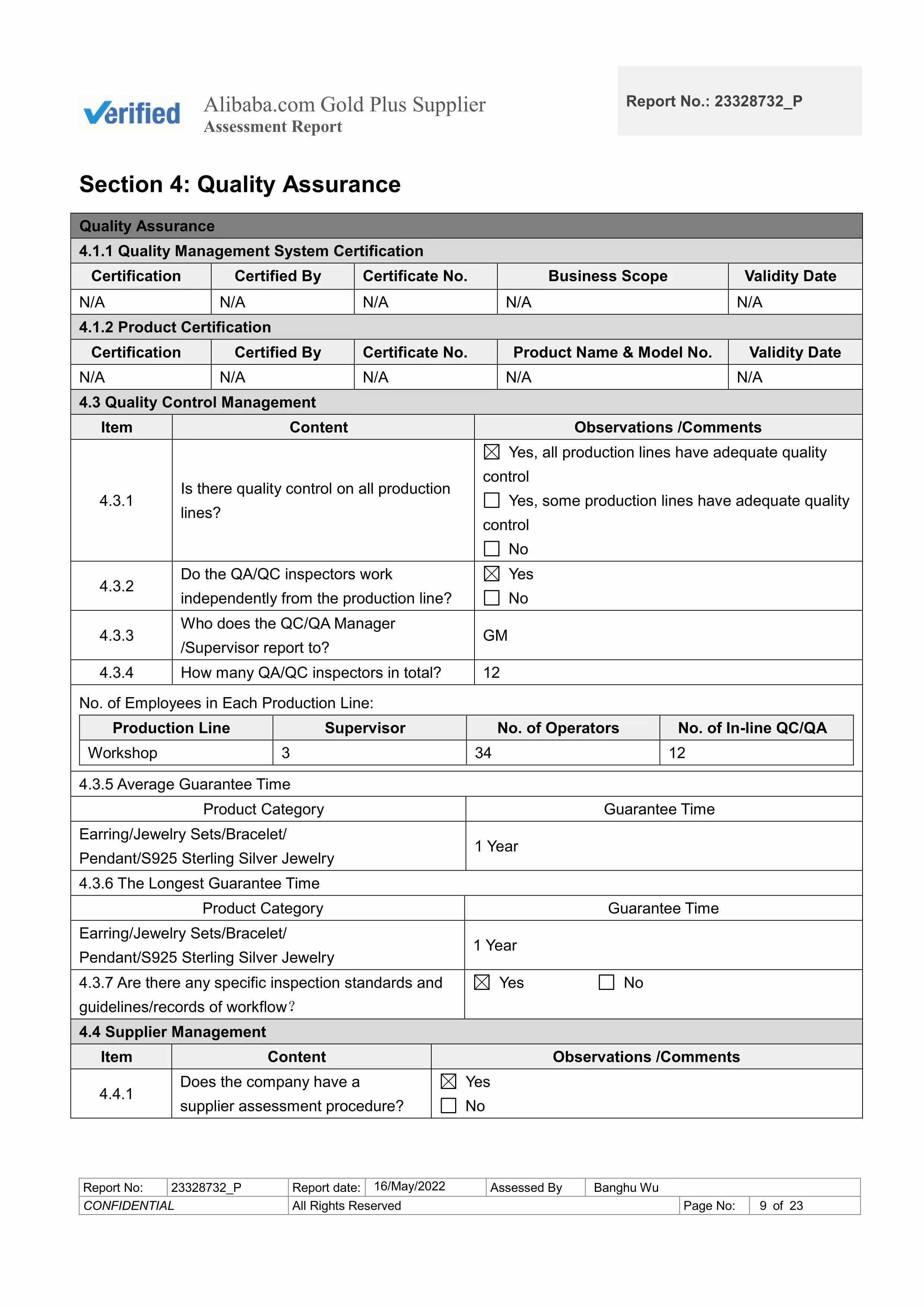

Quality Assurance

Issuing authority : SGS

Valid period : 2021/4/6 - 2022/5/6

Quality Assurance

HD as a jewelry strength supplier and manufacturer, in terms of our historical experience of more than 15 years in the business, our quality is not only guaranteed by word-of-mouth from customers all over the world, but also by written procedures of testing reports.We can assure you that1. our company has a supplier evaluation process, and we will provide you with relevant written documents at the time of your purchase, so that you can be assured that our cooperation process is smooth and unhindered.2. that we have established and implemented standard procedures for the review and approval of procurement contracts, that there are no rules and that a completed set of standard procedures ensures that cooperation is standardized.3. that we maintain supplier evaluation reports.4. the company's procurement documentation is sufficient to ensure product safety control and customer requirements.5. We will randomly check the products after final packaging to ensure that the goods sent out are problem-free.

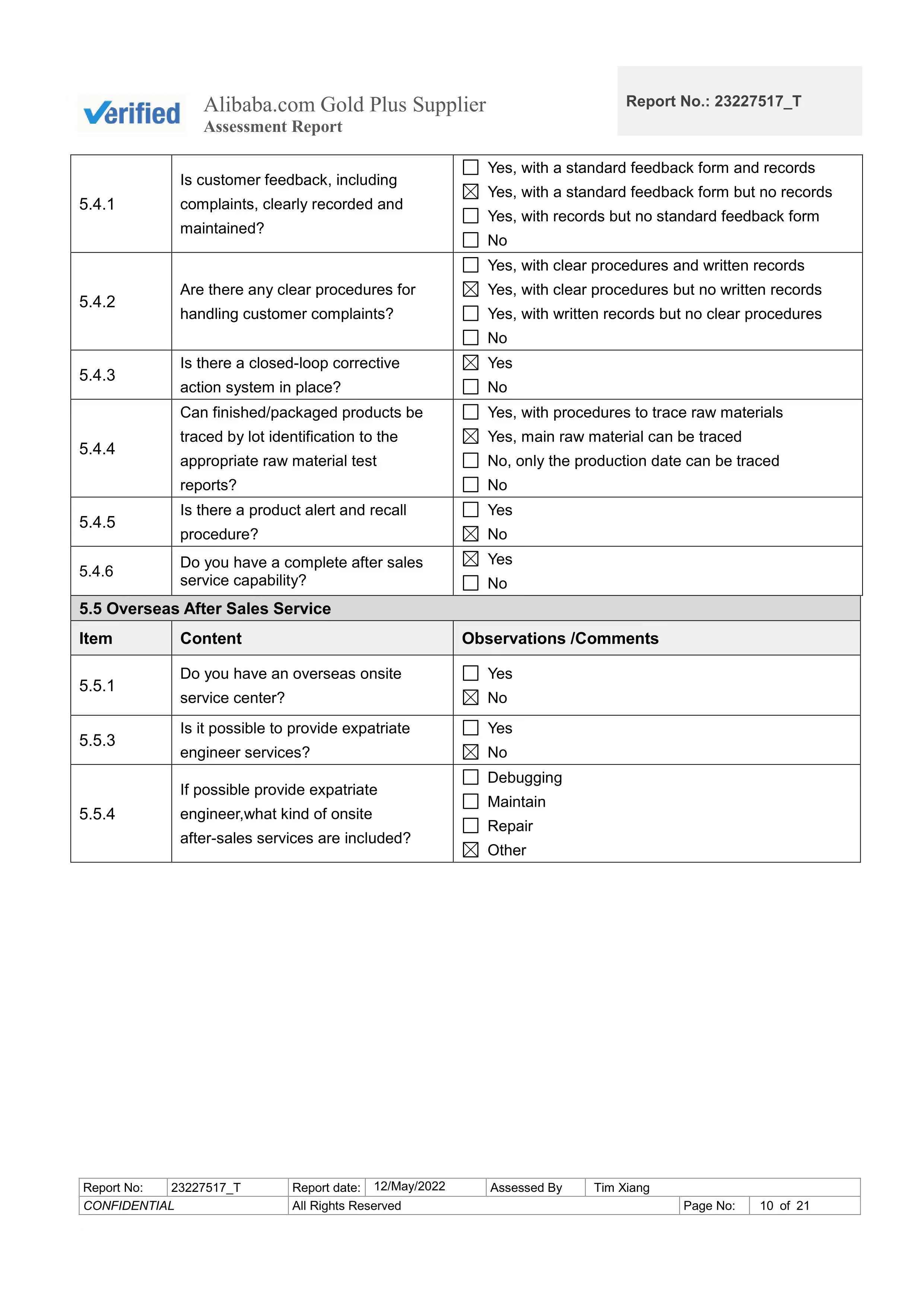

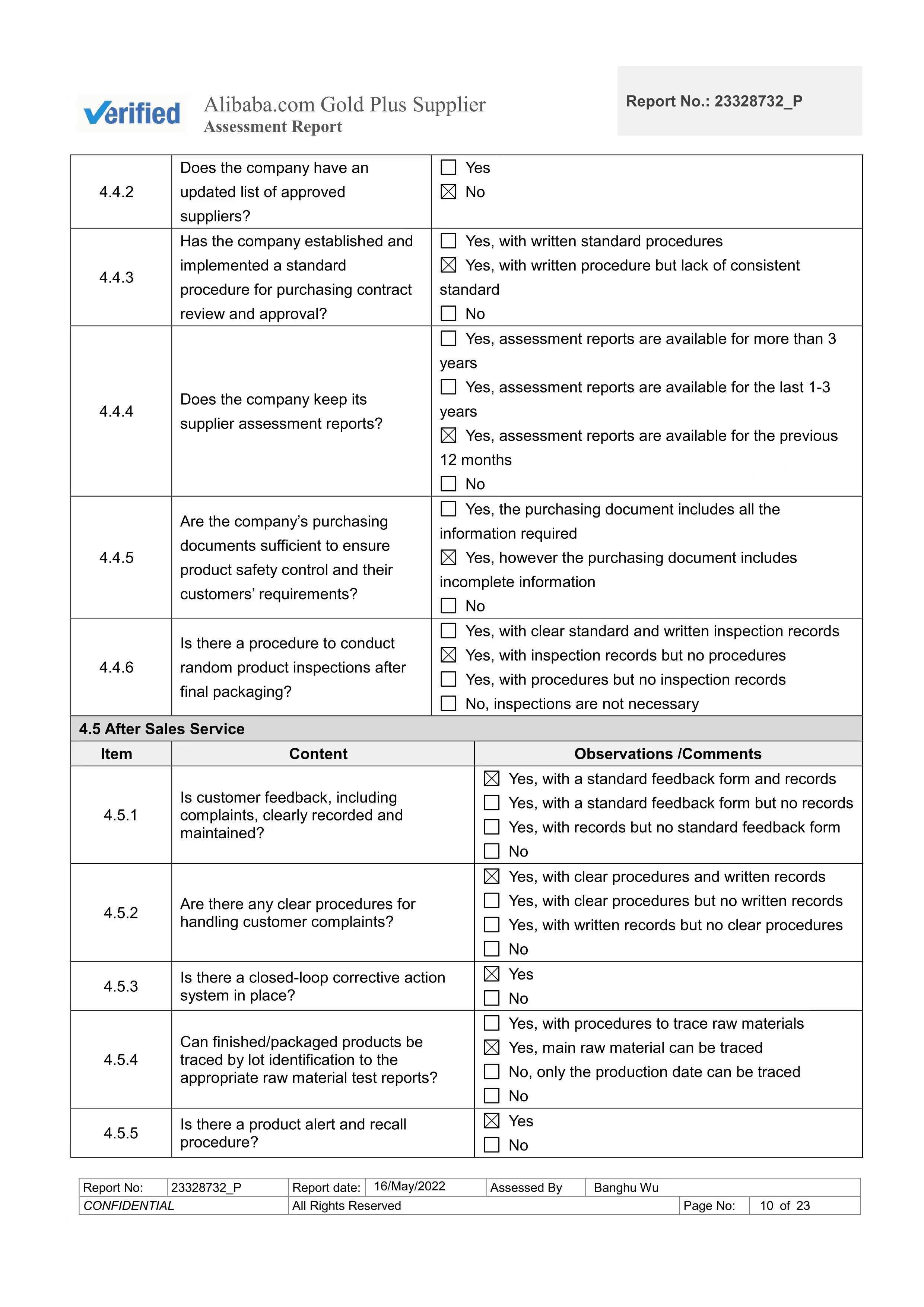

Aftersales Service

Quality after-sales service often determines whether customers will become our stable partners, and we have a standard service system in this segment.1. we have a standard feedback form, when the customer feedback, clear records and timely problem solving.2. there are clear procedures for handling customer complaints.3. have a closed-loop corrective action system.4. finished/packaged products can be traced to the corresponding raw materials.5. Have complete after-sales service capability

-

-

-

-

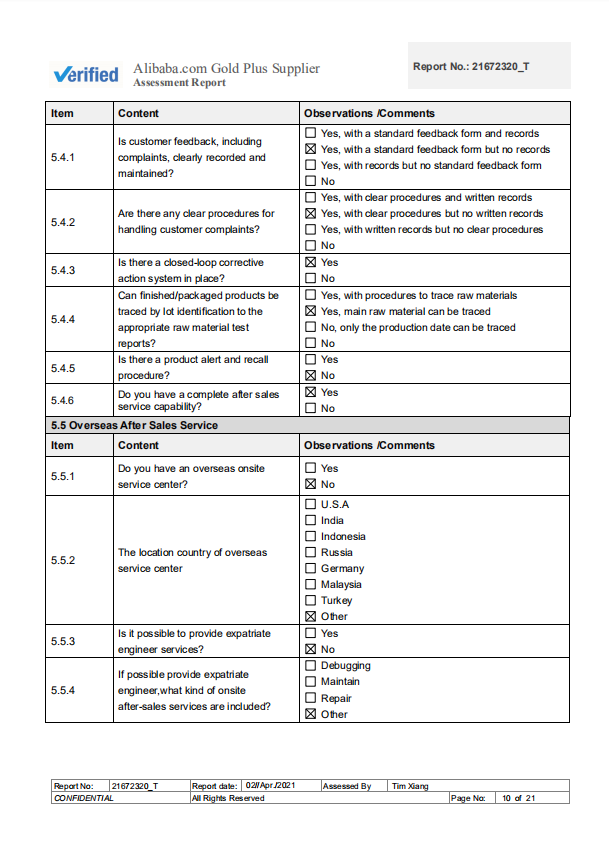

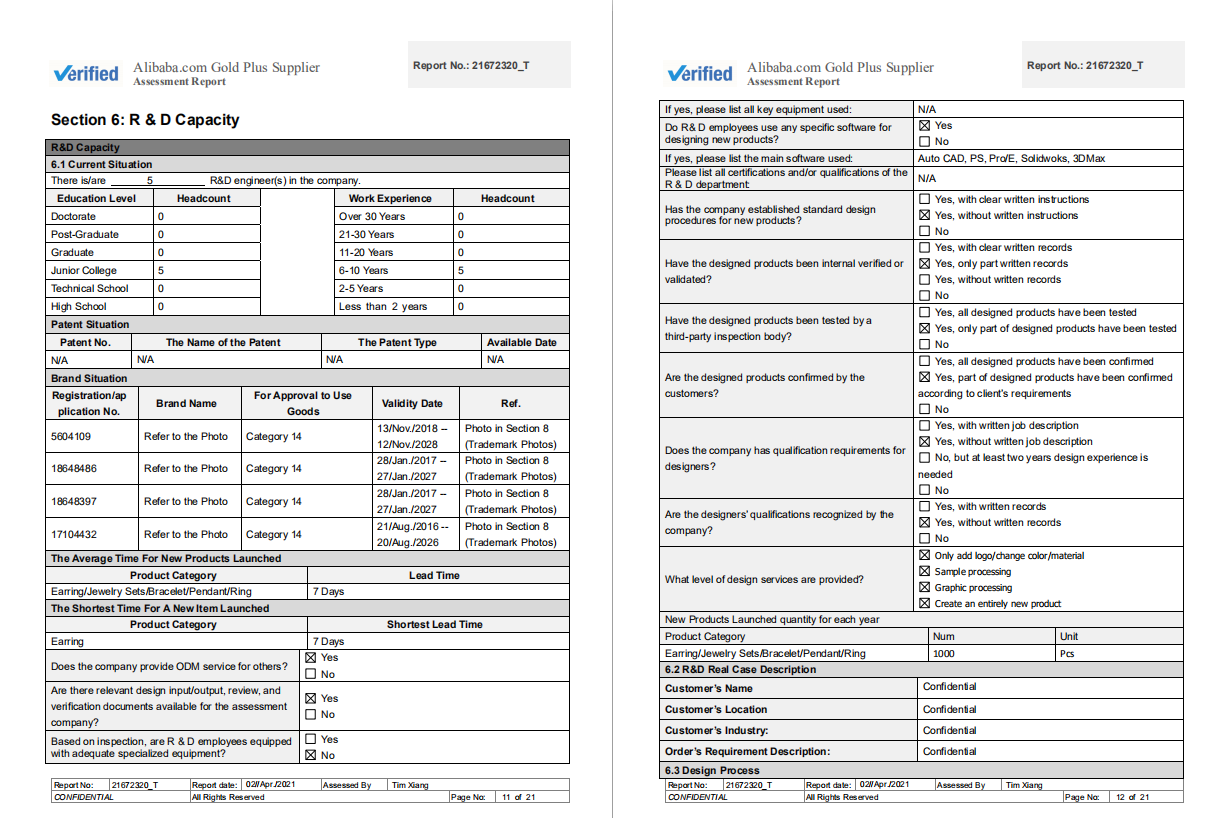

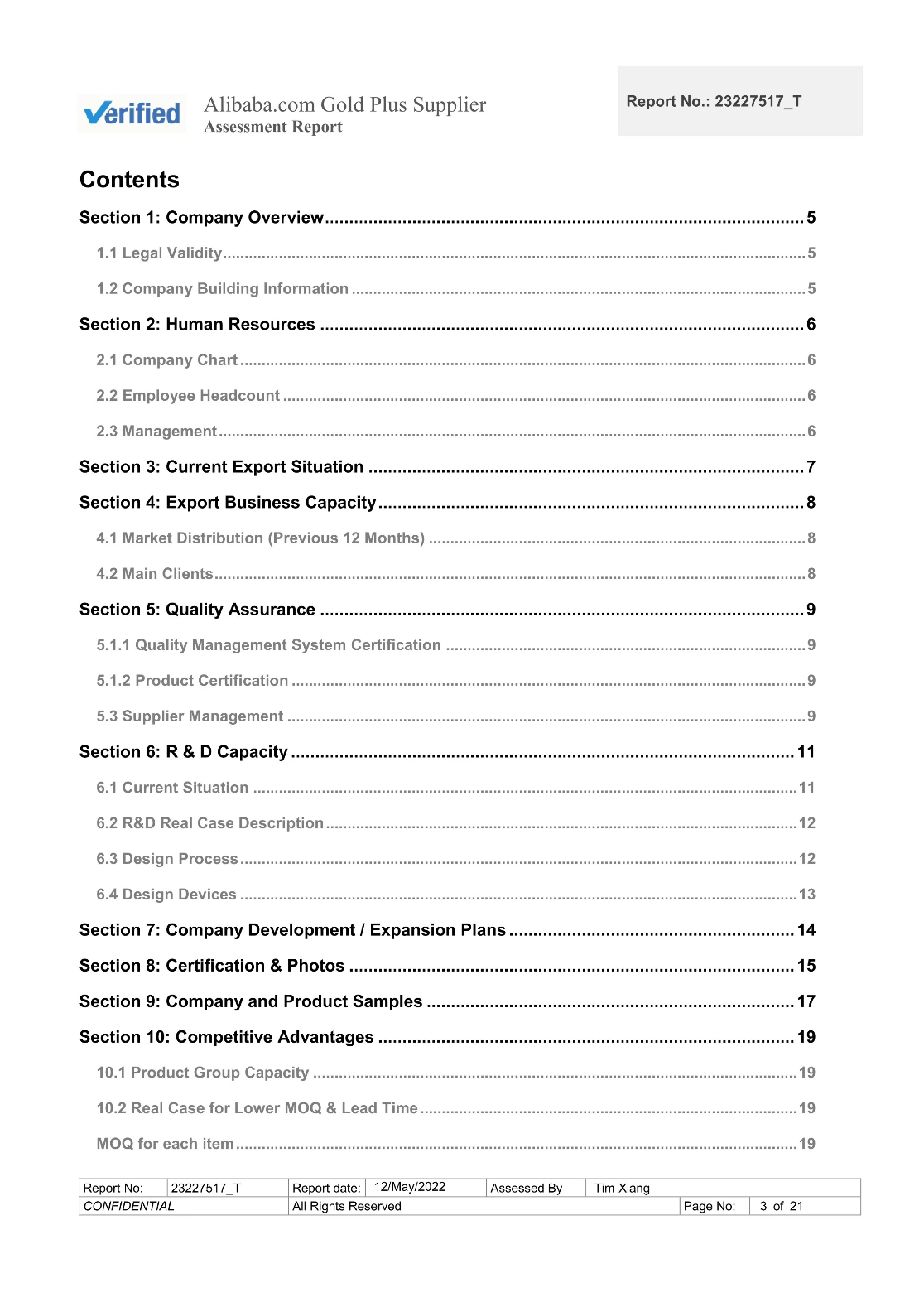

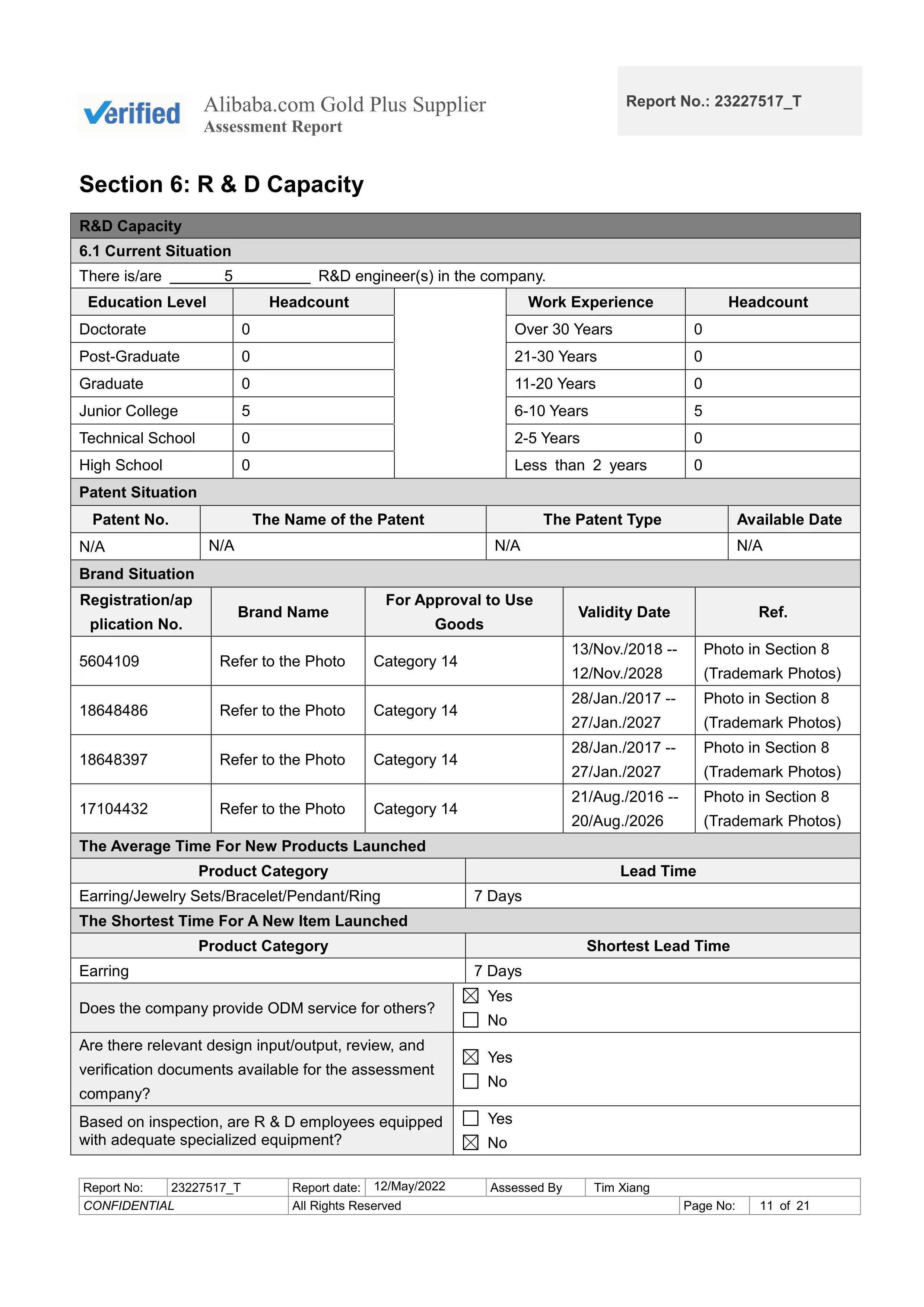

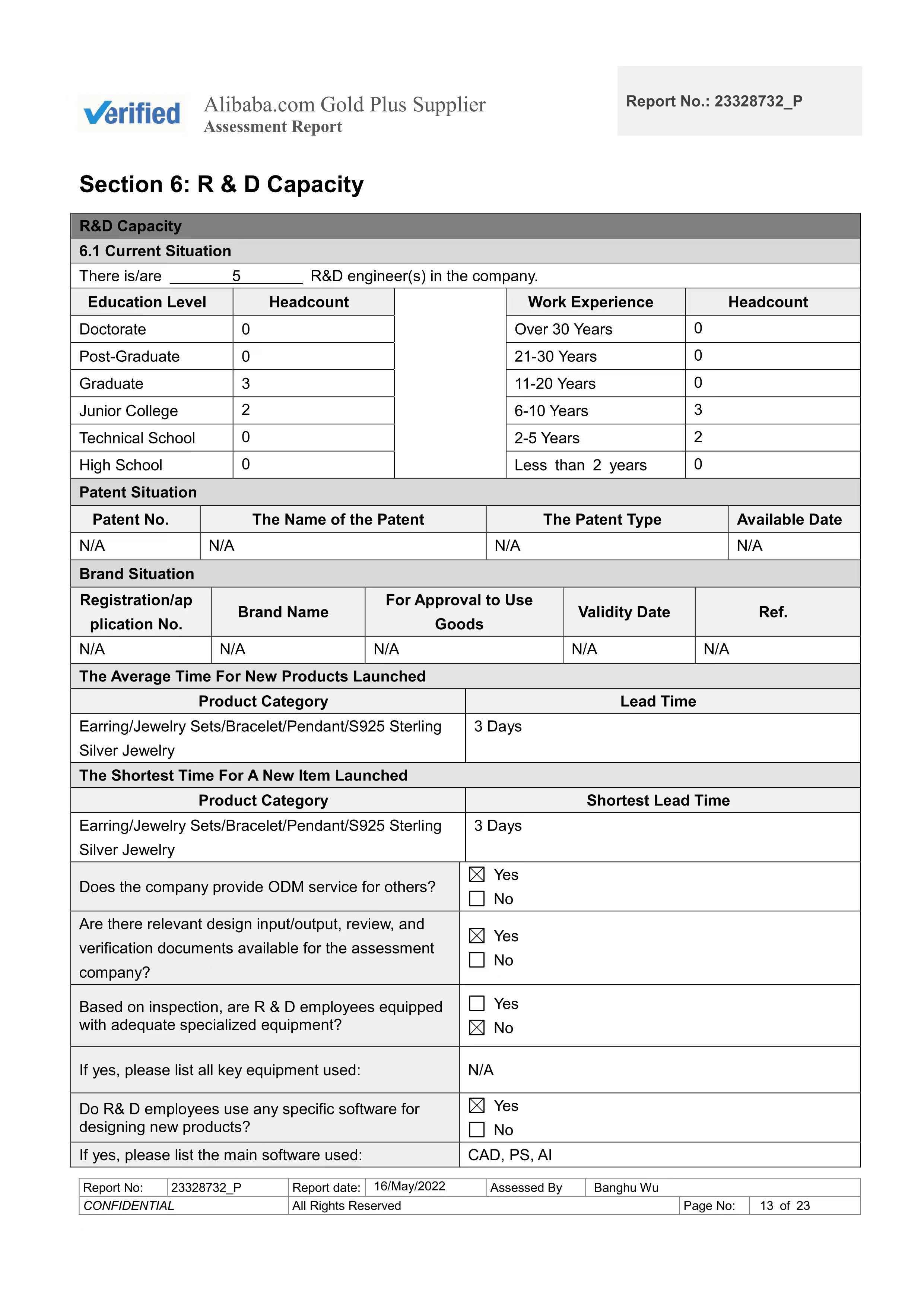

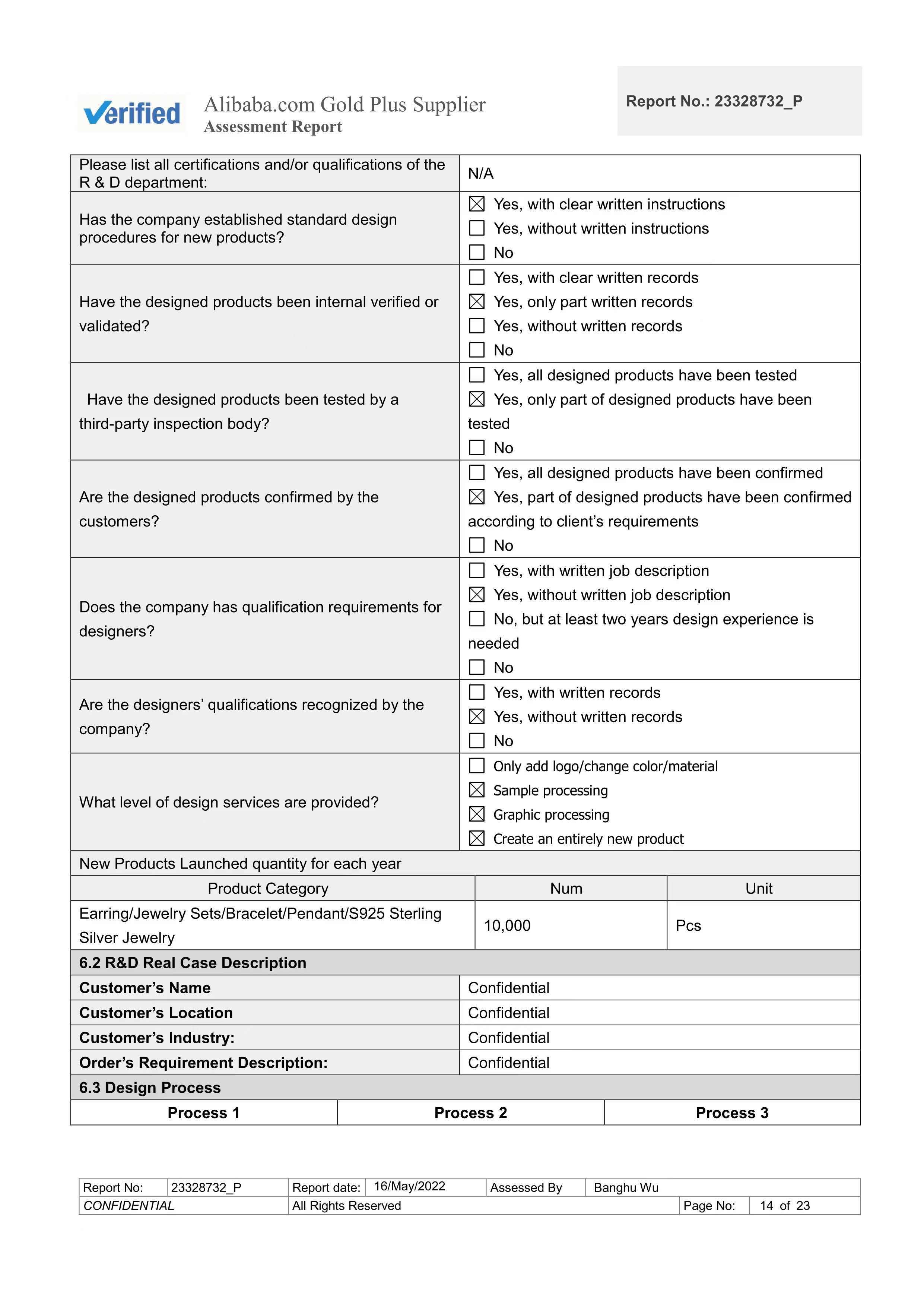

R&D Capacity

Issuing authority : SGS

Valid period : 2021/4/6 - 2022/5/6

R&D Capacity

Our product development capabilities are specifically demonstrated in the following areas.1. ODM services for customers within 7 days.2. with relevant design input/input, review and other processes.3. dedicated equipment equipped for R&D staff.4. having specific software applications for R&D staff in designing new products.5. having a standard set of standard design procedures for new products.6. the designed new products must be validated internally before they are finally released.7. designed products are verified by third-party inspection agencies.8. the designed products are recognized by customers and praised continuously.9. before being recognized by the company.10. design services that can be provided: adding logos/changing colors/materials only; sample processing; graphic processing; creating brand new products, etc.Our R&D capability is accumulated through time and technology, our capability is far beyond the description on the report, if you are interested in us, you can contact us and come to visit our factory, we welcome you anytime!

-

-

-

-

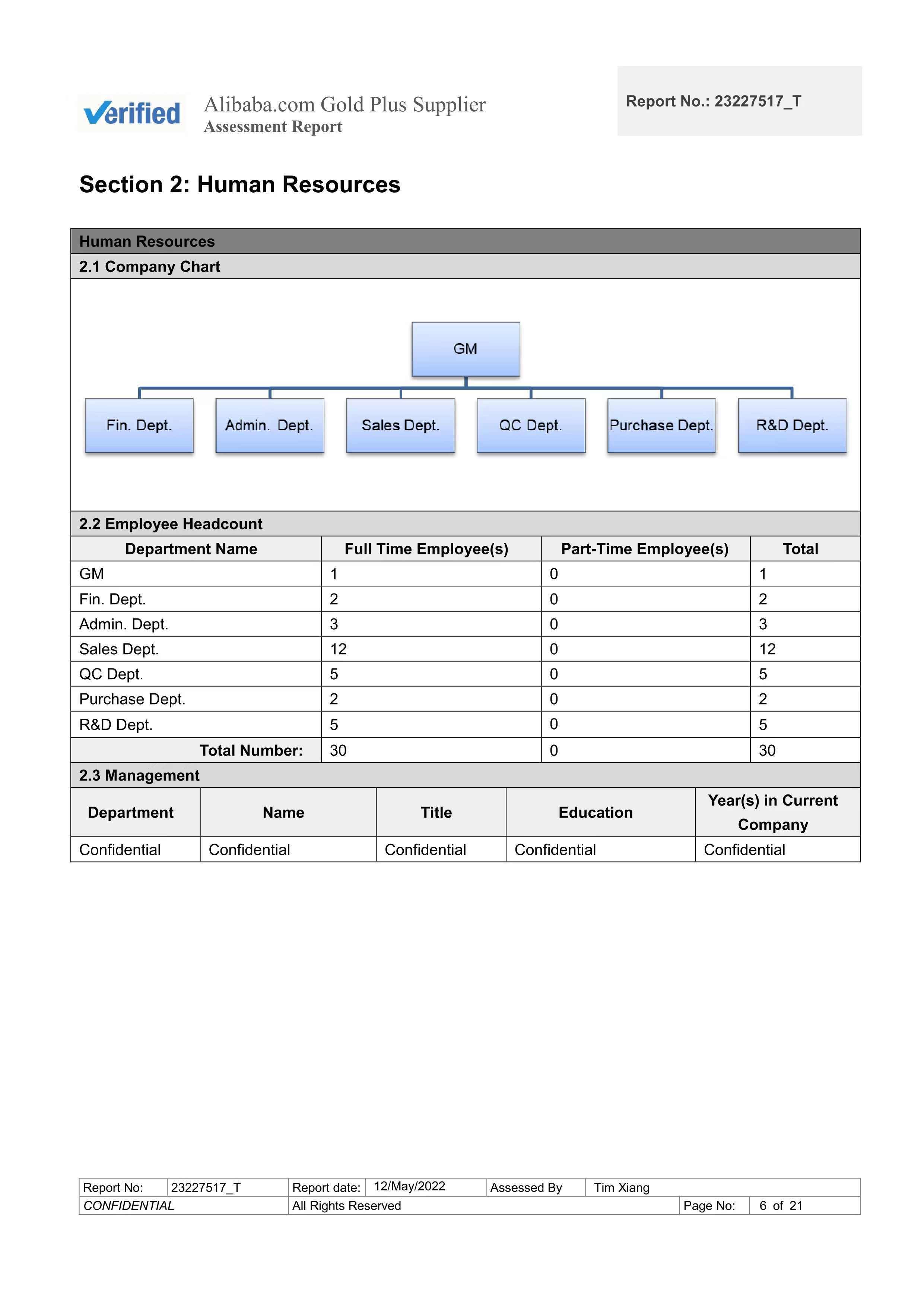

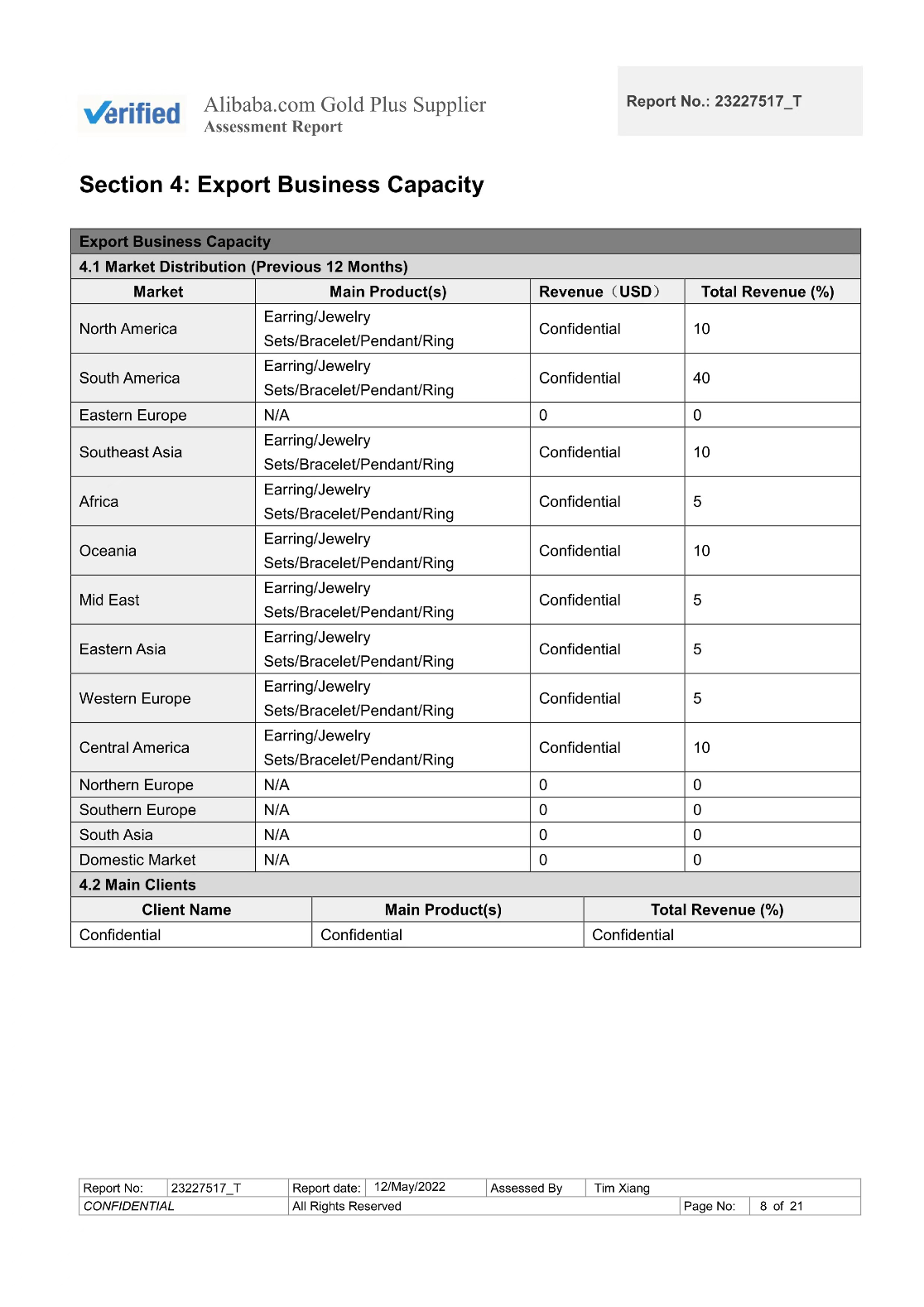

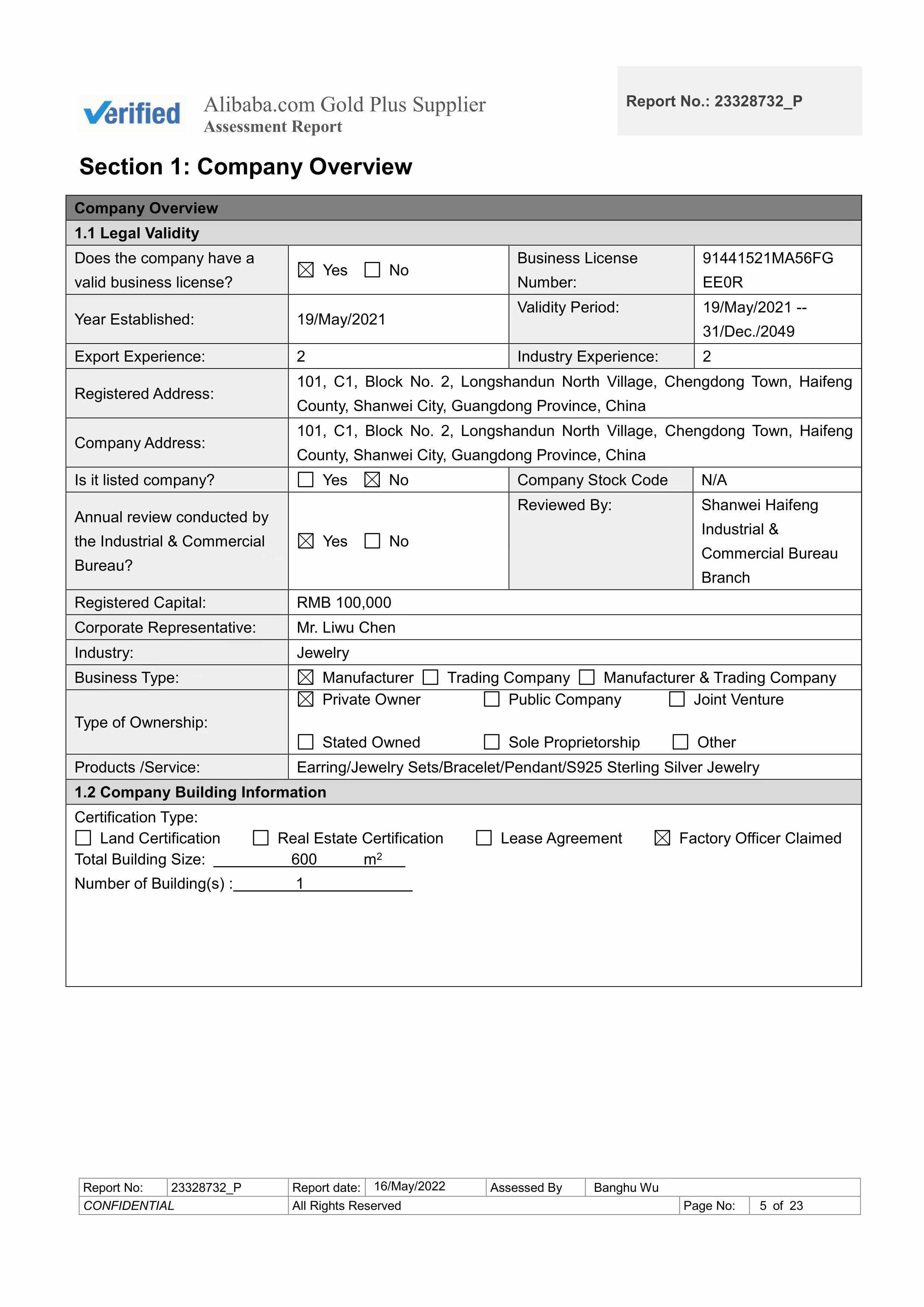

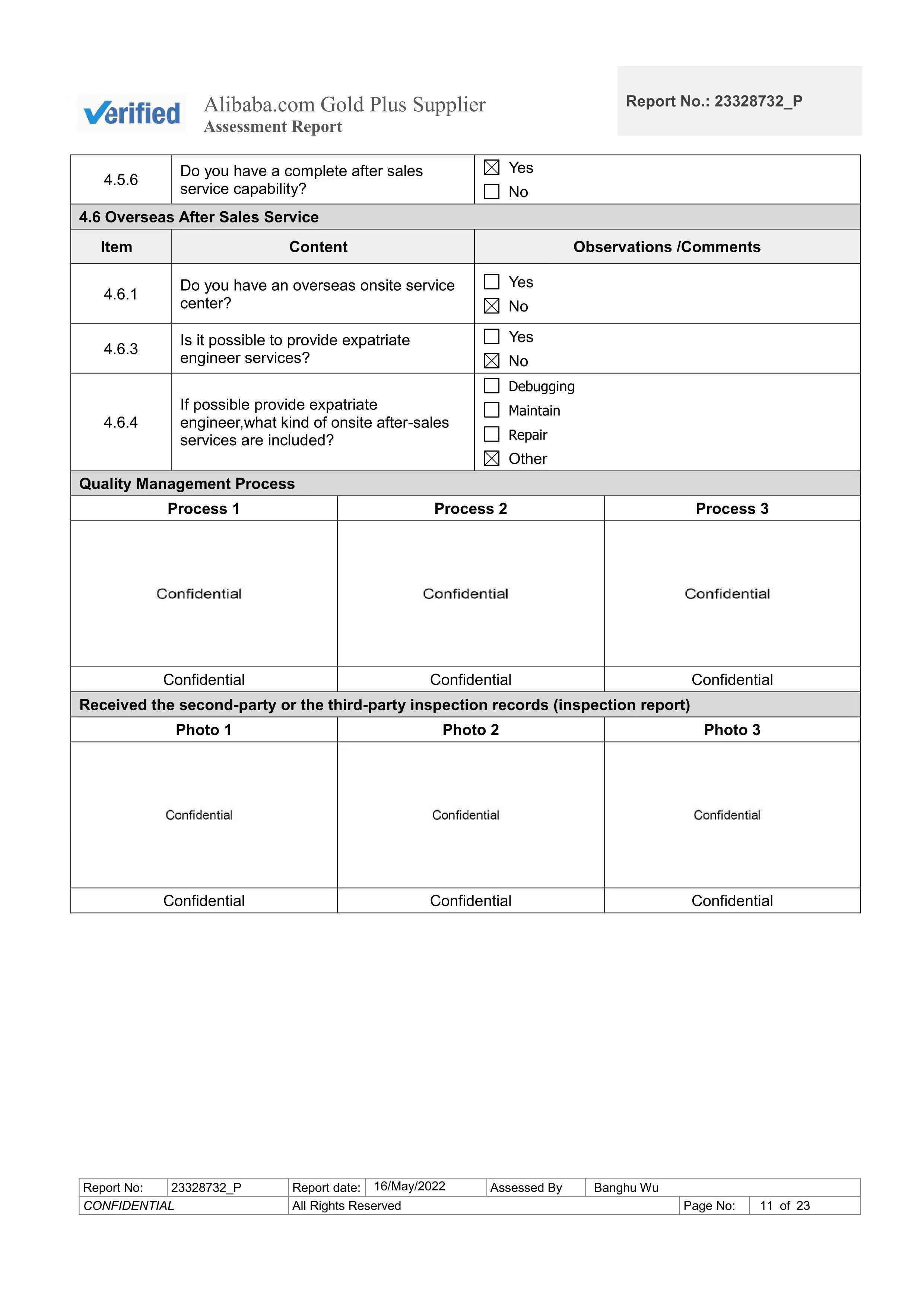

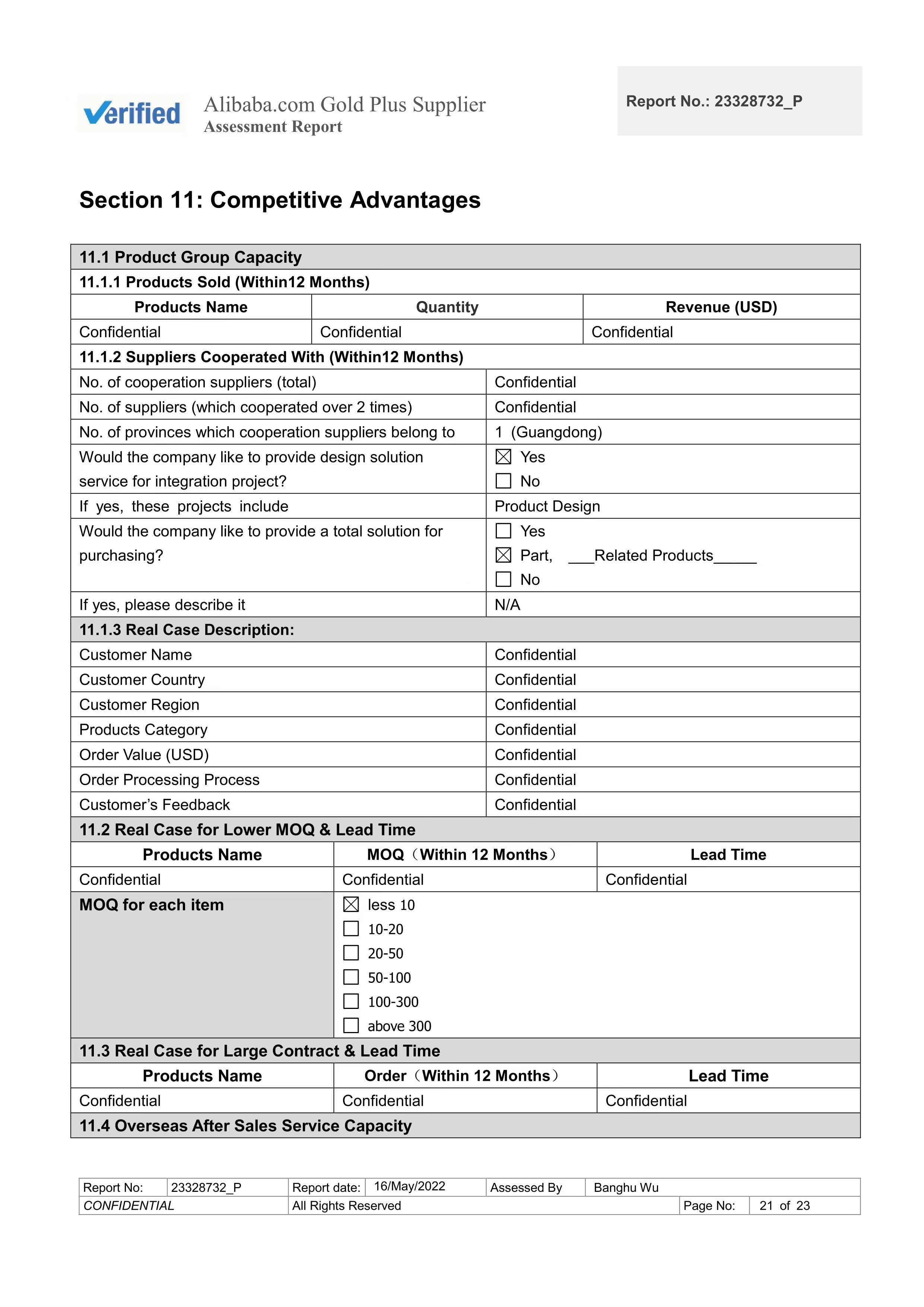

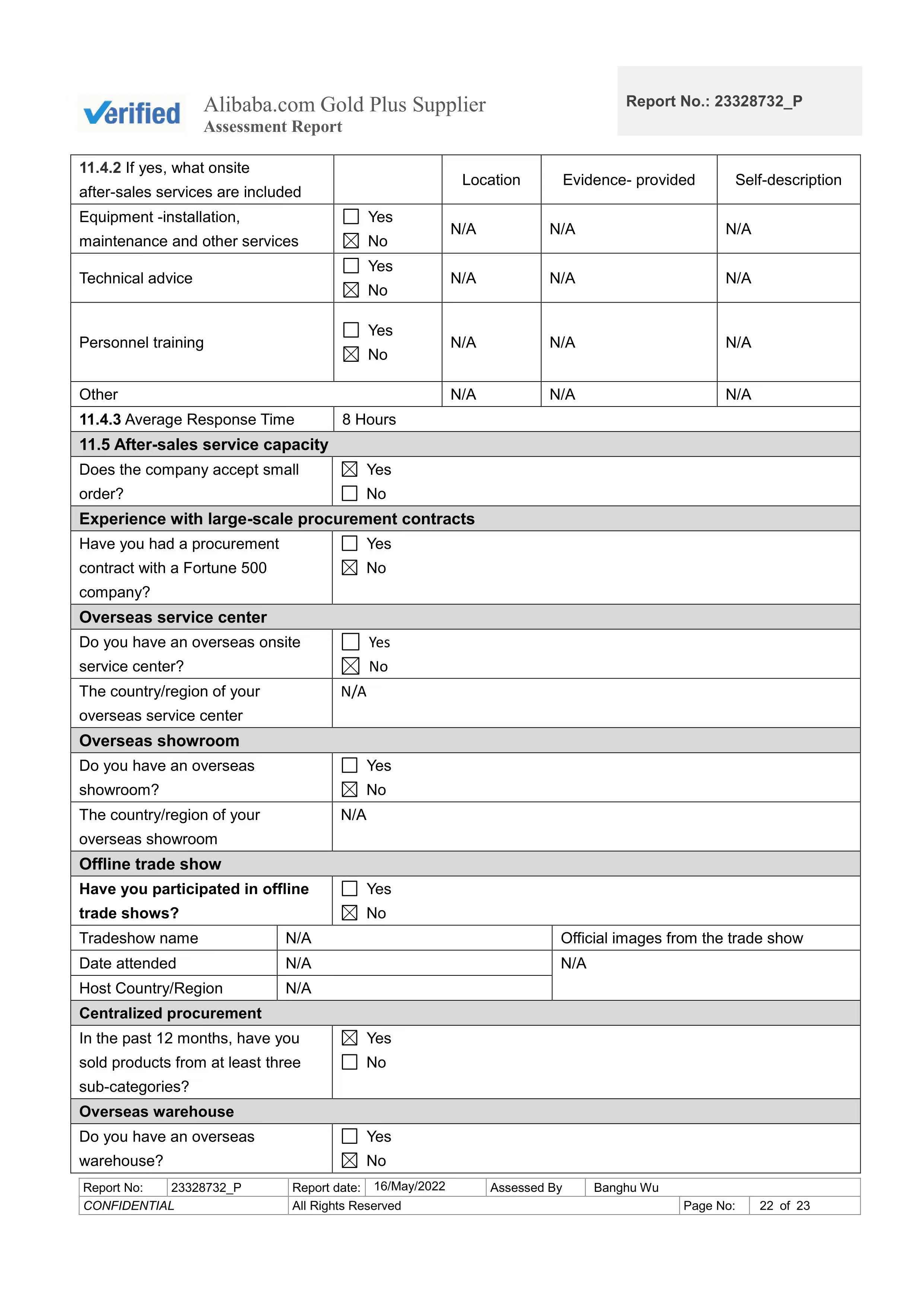

Supplier Assessment Report

Issuing authority : SGS

Valid period : 2022/5/13 - 2023/5/12

Certicifation

Hengdian is a company committed to providing high quality products and services. In order to ensure the effectiveness and sustainability of supply chain management, Hengdian has adopted SGS supplier assessment report. In this article, we will introduce the SGS supplier assessment report of Hengdian Company.

Evaluation criteria.

The SGS supplier assessment report provides a comprehensive assessment of the supplier, which includes the following aspects:

1. Quality management system: Suppliers must have an effective quality management system and be able to demonstrate that the system meets international standards.

2. Production capacity and capability: The supplier must have sufficient production capacity and capability to meet market demand.

3. Product quality: The supplier must provide products that meet the appropriate standards and regulations and must not have quality problems.

4. Cost effectiveness: The supplier's price must be in line with the market and not higher than the market price.

5. Social responsibility: Suppliers must comply with relevant laws and regulations and have a good sense of social responsibility.

Assessment Process

The SGS Supplier Assessment Report takes a combination of regular and ad hoc assessments.

The periodic assessment is conducted once a year, and the supplier is inspected and evaluated on site by SGS professionals. The assessment includes the supplier's quality management system, production capacity and capability, product quality and other aspects. The assessment results classify suppliers into four grades of excellent, good, fair and poor according to their scores.

Interim assessment is conducted when problems are found with suppliers and is organized and implemented by the relevant departments of Hengdian. The assessment mainly includes whether there are quality problems with the products provided by the supplier, whether the delivery is on time, etc. If the supplier assessment score is low, Hengdian will take corresponding measures, such as suspending cooperation or adjusting the purchase volume.

Assessment Results.

The assessment results of the SGS Supplier Assessment Report include the following:

1. the assessment results of all suppliers, classified according to the grades of excellent, good, fair and poor

2. the scores of each assessment index, including the five aspects of quality management system, production capacity and capability, product quality, cost effectiveness and social responsibility

3. Strengths and weaknesses of suppliers, and suggestions for improvement.

Through the SGS supplier evaluation report, Hengdian is able to understand the performance of each supplier and identify and solve problems in time, so as to ensure the quality and efficiency of production and service.

SGS supplier assessment report is an important management tool that can help companies better manage their supply chain and improve production efficiency and product quality. Through the assessment report, Hengdian can identify and solve various problems in time, maintain a good relationship with suppliers and promote sustainable development of the enterprise.

-

-

-

-

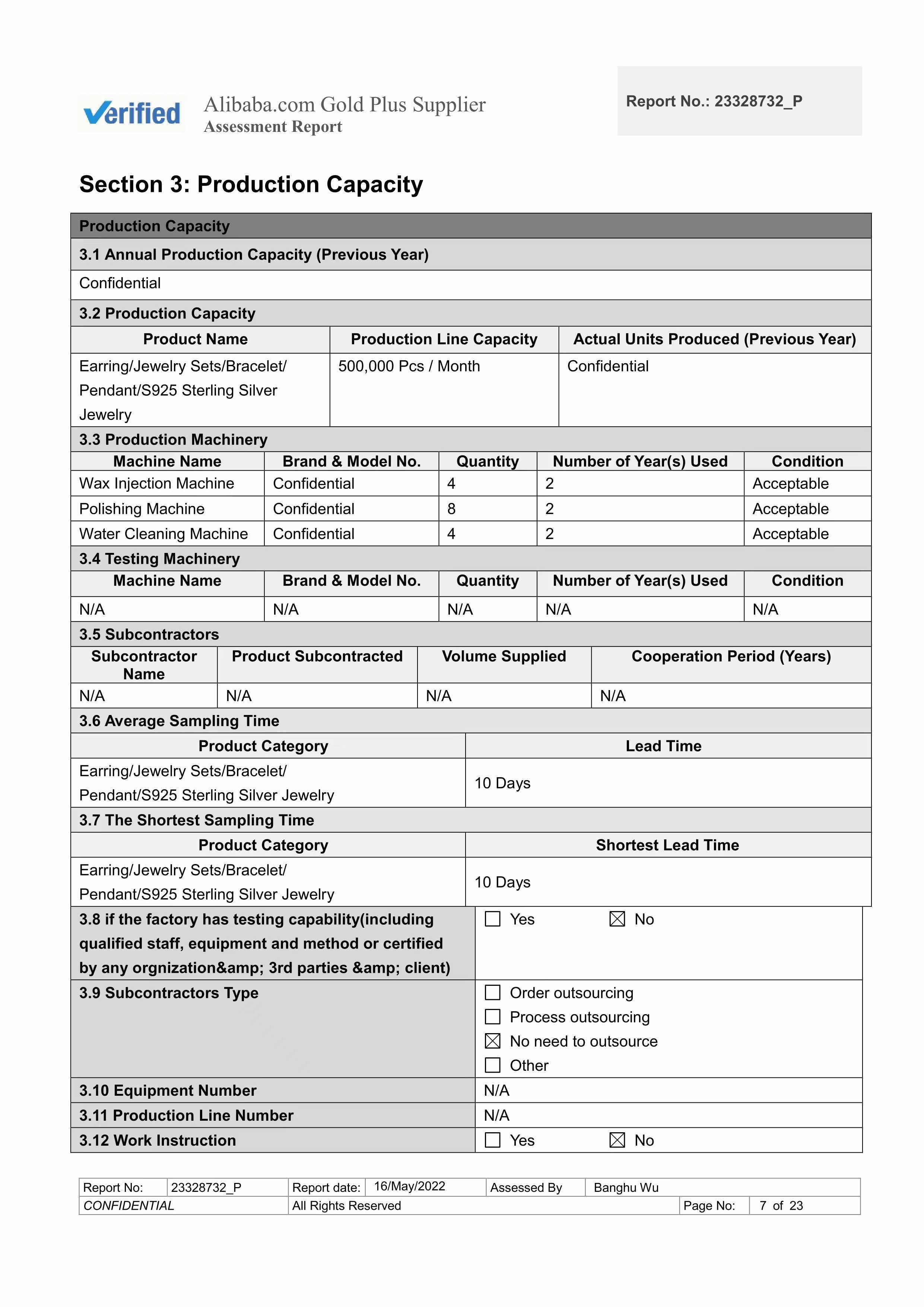

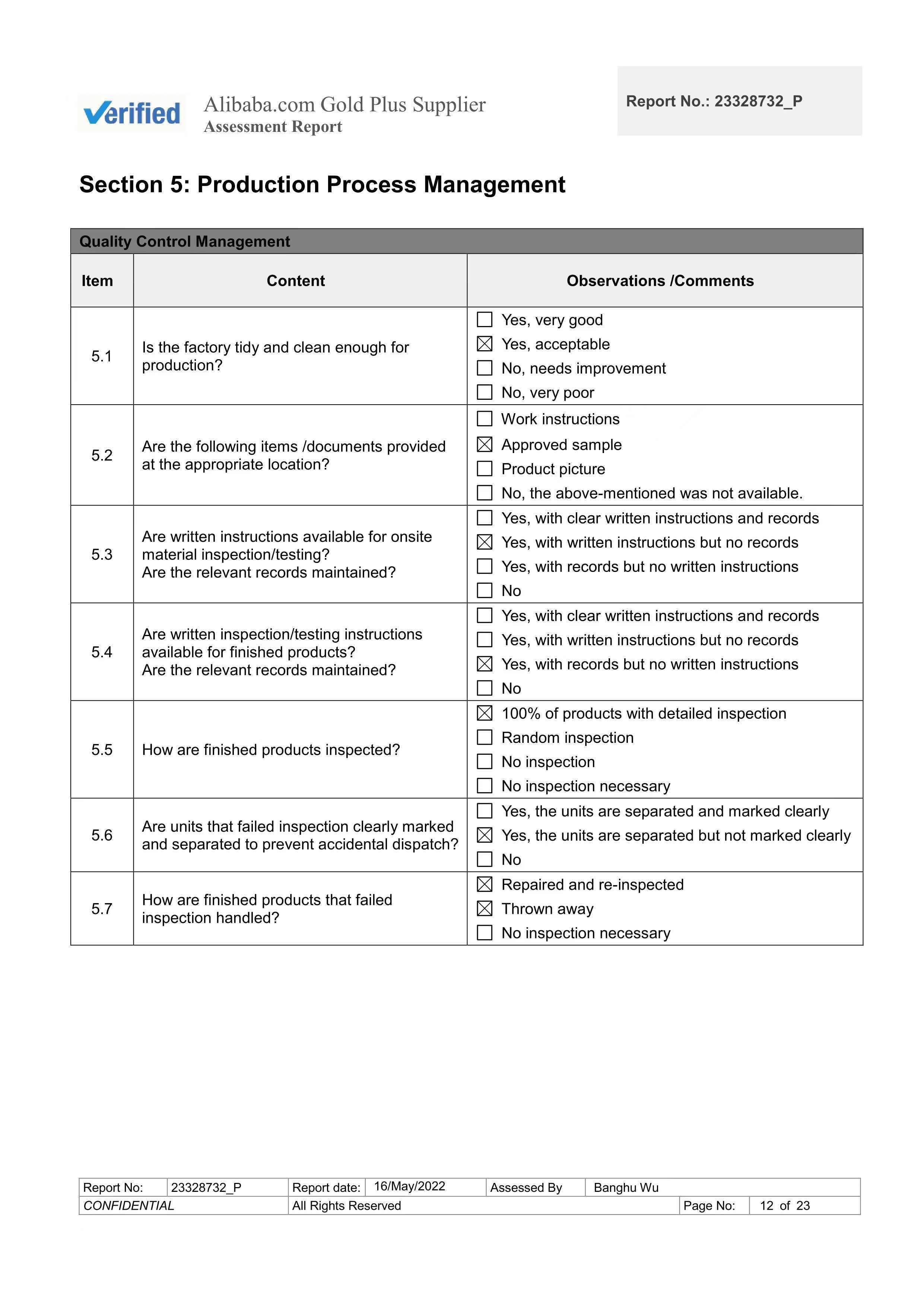

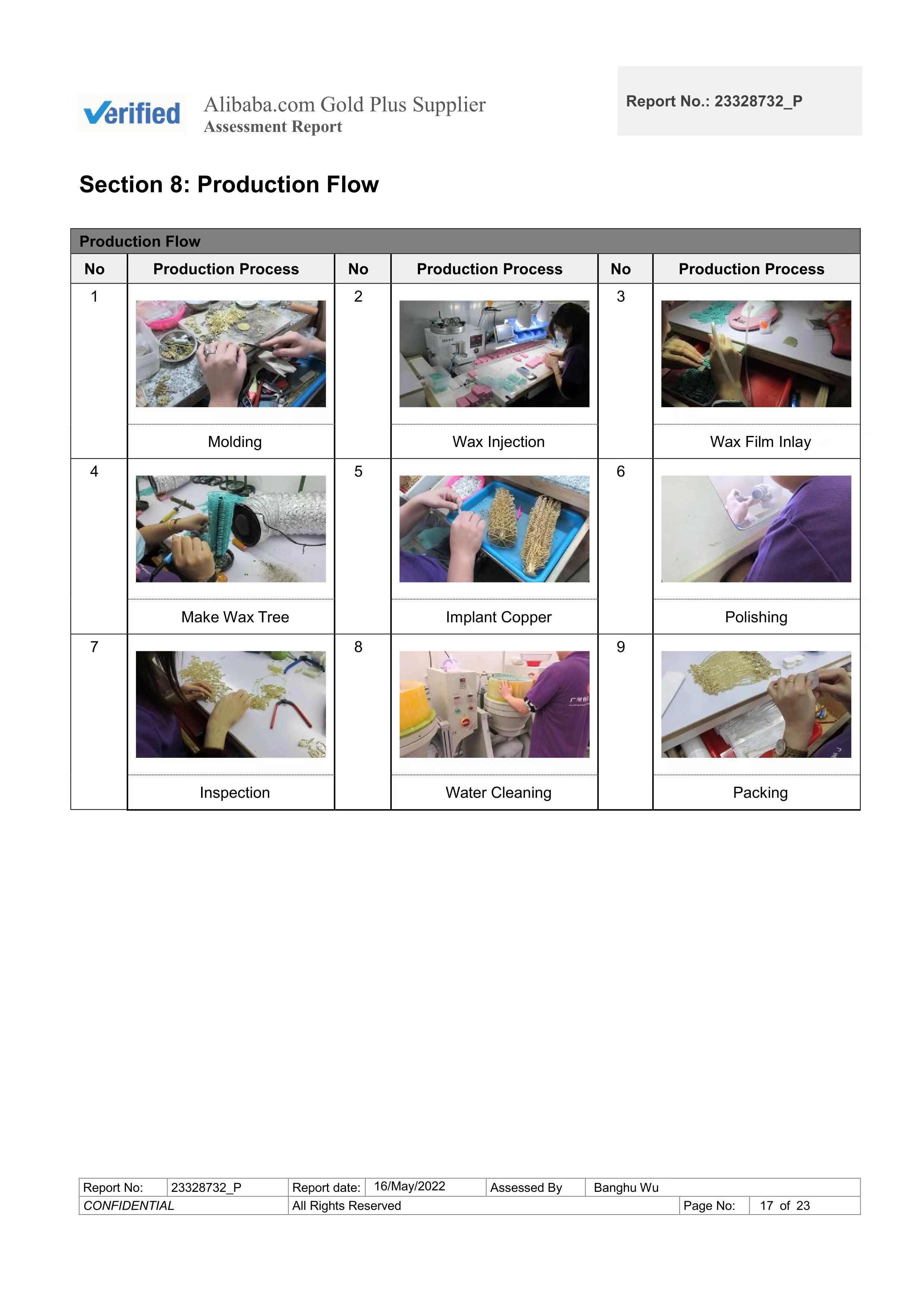

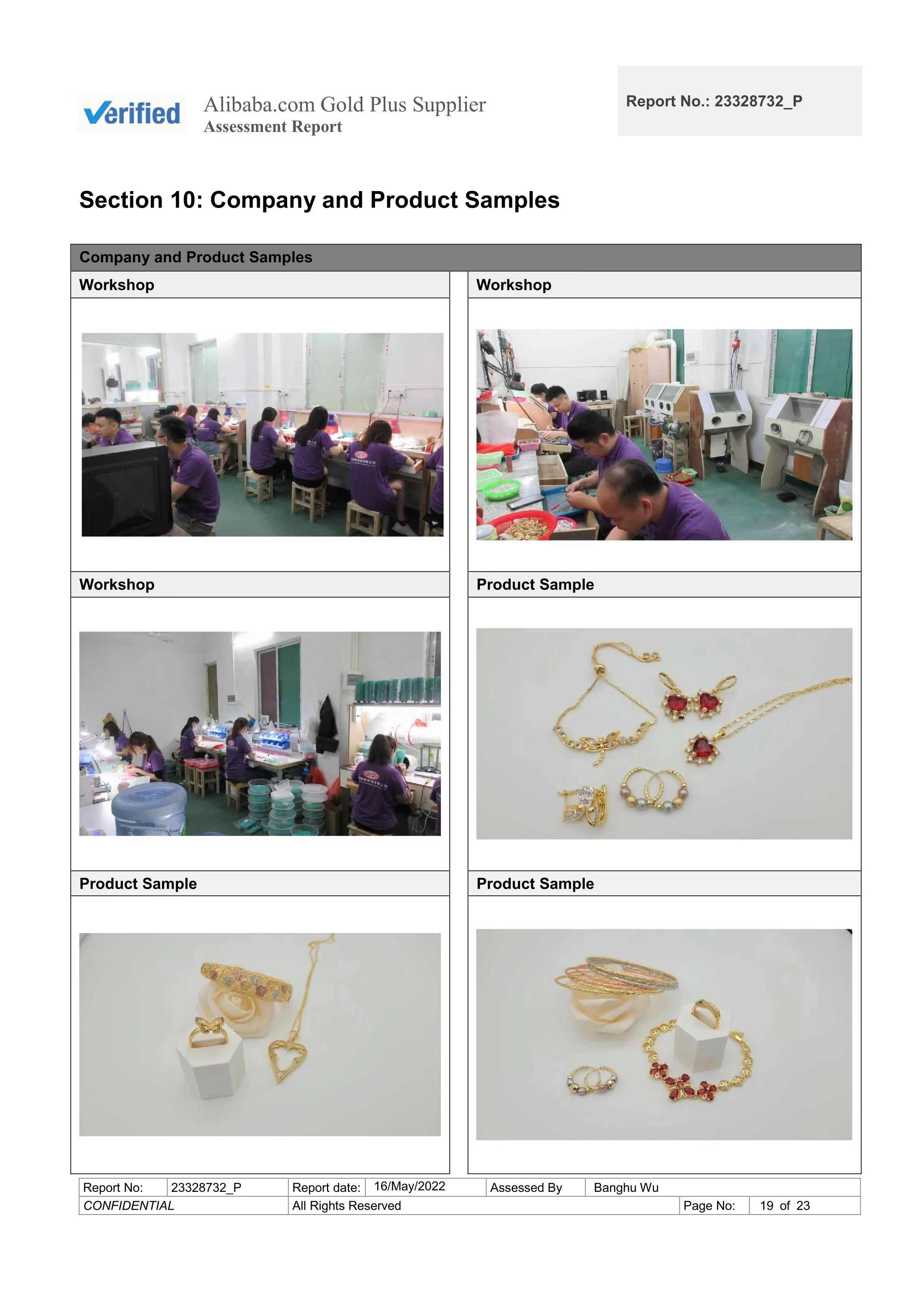

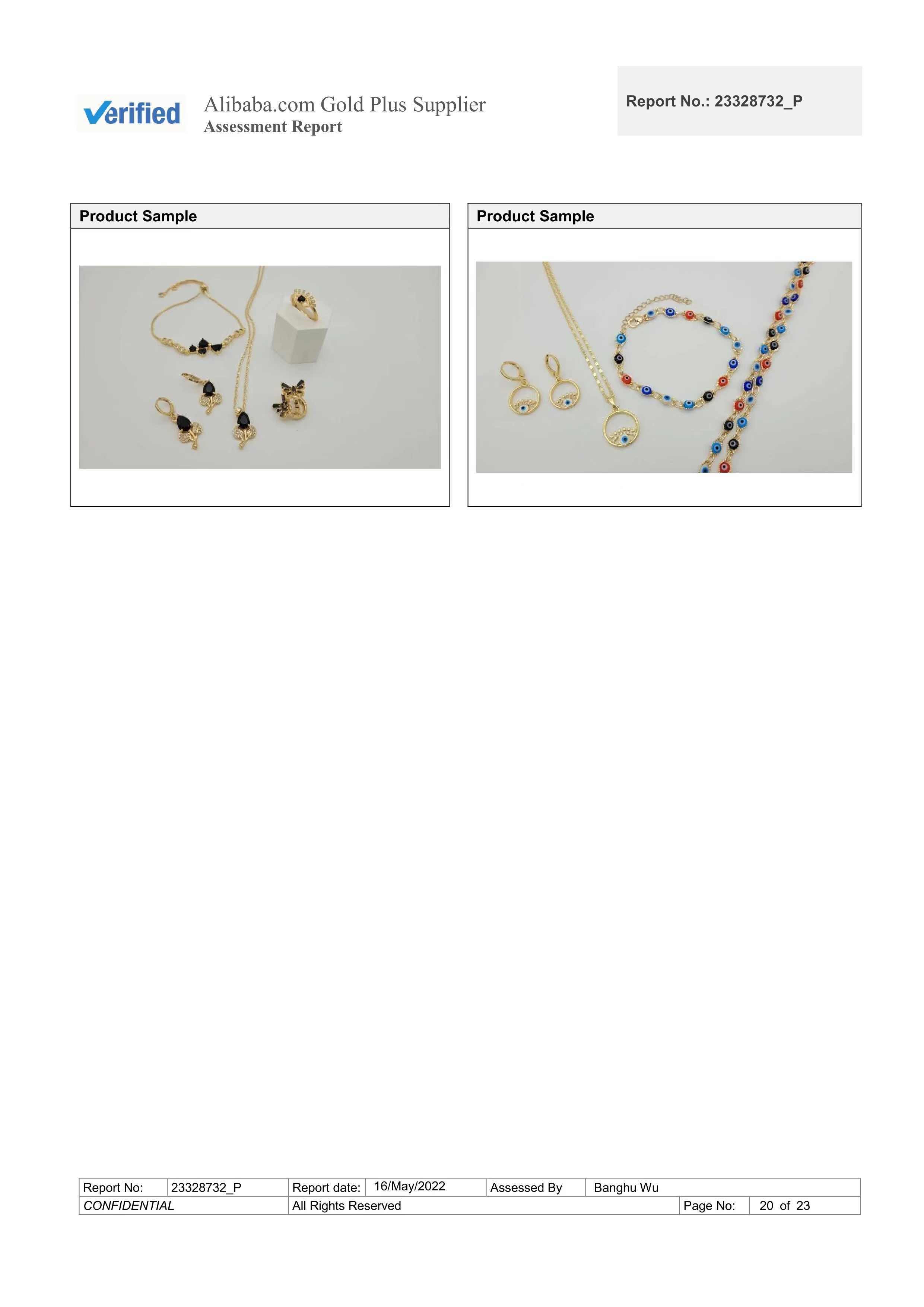

Factory Assessment Report

Issuing authority : SGS

Valid period : 2022/5/16 - 2023/5/12

Certicifation

In order to ensure the effectiveness and sustainability of factory management, Hengdian uses the SGS Factory Assessment Report. The assessment standard SGS factory assessment report provides a comprehensive assessment of the factory.

It mainly includes the following aspects:

1. Production capacity and capability: The factory must have sufficient production capacity and capability to meet market demand.

2. Production equipment: The factory equipment must meet the standards and must be regularly maintained and tested to ensure normal operation of the equipment.

3. Raw material procurement and management: The factory must purchase raw materials that meet quality standards and establish scientific management methods to ensure that the quality of raw materials meets the requirements.

4. Product quality: The products produced by the factory must conform to the corresponding standards and regulations, and there must be no quality problems.

5. Environmental protection: The factory must comply with relevant laws and regulations and have a good sense of environmental protection. The assessment process SGS factory assessment report adopts a combination of regular assessment and interim assessment. The periodic assessment is conducted once a year, and the factory is inspected and assessed on site by SGS professionals. The assessment covers the factory's production capacity and capability, production equipment, raw material procurement and management, product quality, environmental protection and other aspects.

The assessment results classify the factories into four grades of excellent, good, fair and poor according to their scores. The interim assessment is conducted when problems are found in the factory and is organized by the relevant department of Hengdian.

The assessment mainly includes whether the environmental protection of the factory meets the standards and whether the equipment is operating normally.

Assessment results The assessment results of SGS factory assessment report include the following:

1. The assessment results of the factory, classified according to the grades of excellent, good, fair and poor.

2. The scores of each assessment index, including five aspects such as production capacity and capability, production equipment, raw material procurement and management, product quality and environmental protection.

3. Strengths and weaknesses of the factory, and suggestions for improvement. Through the SGS factory assessment report, Hengdian can understand the performance of the factory, find and solve problems in time, so as to ensure the quality and efficiency of production and service.

SGS factory assessment report is an important management tool that can help companies to better manage their factories and improve production efficiency and product quality. Through the assessment report, Hengdian can identify and solve various problems in time, maintain good cooperation with suppliers and promote the sustainable development of the company.

-

-

-

-

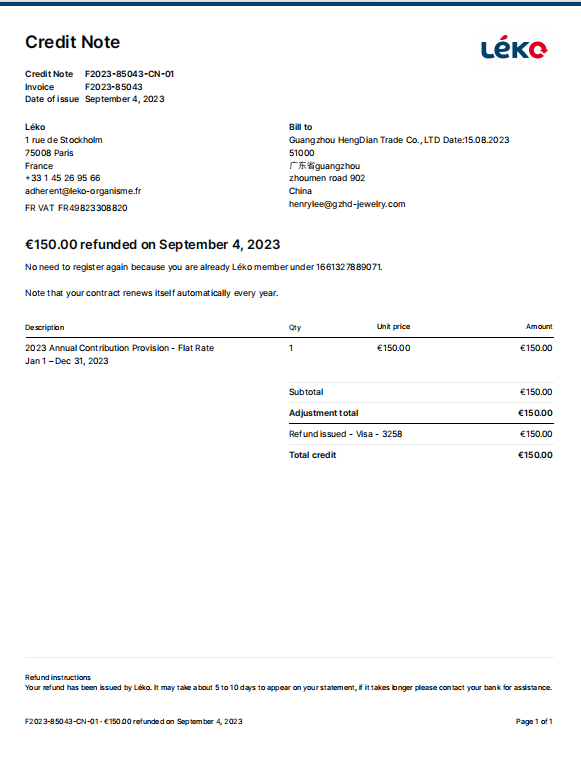

French EPR certificate

Certificate No : F2023- 85043- CN- 01

Issuing authority : leko

Valid period : 2023/1/1 - 2023/12/31

"Hengdian Jewelry's Green Certification: Valid EPR in Germany and France"

Introduction:Hengdian Jewelry Company proudly announces its attainment of the prestigious EPR (Extended Producer Responsibility) certificate, an affirmation of our dedication to environmental sustainability. This article will shed light on the importance and validity of the EPR certificate in both Germany and France, while also introducing you to our core specialization: the wholesale of fashion jewelry crafted from responsibly sourced gold-plated brass with zircon inlay. We extend an open invitation to countries across the globe to explore mutually beneficial jewelry wholesale collaborations with us.Comprehending the Significance of EPR Certification1. Germany: A Pioneer in Green ResponsibilityIn Germany, the EPR certificate serves as a testament to a company's commitment to upholding rigorous environmental standards. It underscores our pledge to minimize waste, foster recycling, and reduce the environmental impact of our jewelry production. By securing the EPR certification in Germany, Hengdian Jewelry Company is aligning itself with the eco-conscious principles that Germany so ardently upholds, emphasizing the importance of environmentally responsible practices.2. France: A Fusion of Elegance and Eco-ConsciousnessIn France, the EPR certificate is a symbol of both fashion and eco-responsibility. It reflects a brand's commitment to crafting exquisite jewelry while adhering to the highest environmental standards. By acquiring the EPR certificate in France, Hengdian Jewelry Company positions itself as a trusted source of jewelry that seamlessly combines sophistication and environmental responsibility, resonating with the discerning French market.Hengdian Jewelry: Your Ultimate Destination for Sustainable Fashion JewelryHengdian Jewelry Company stands as a global leader in the wholesale of fashion jewelry crafted from responsibly sourced gold-plated brass with exquisite zircon inlay. Our acquisition of EPR certificates in Germany and France underscores our commitment to providing eco-friendly jewelry of the utmost quality. Here's why we are the ideal partner for your gold-plated jewelry wholesale needs:1. Artistry Beyond Compare:Our expert artisans seamlessly blend traditional craftsmanship with contemporary design sensibilities, ensuring each piece embodies the highest quality standards.2. Ethical Sourcing:We understand the significance of eco-conscious jewelry production. Our gold-plated brass is responsibly sourced, and our zircon inlays are ethically procured, highlighting our dedication to sustainability.3. A Myriad of Designs:Our collection offers a diverse array of designs to cater to a variety of preferences. From timeless classics to cutting-edge trends, we provide a selection that appeals to a global clientele.4. Competitive Wholesale Rates:We present competitive pricing for our wholesale partners, enabling your business to thrive while delivering top-quality jewelry to your customers.5. International Wholesale Collaboration:Hengdian Jewelry Company enthusiastically welcomes partners from all corners of the globe to engage in jewelry wholesale collaboration. With our EPR certificates in Germany and France, we are equipped to serve the international market while upholding the highest standards of quality and environmental responsibility.Conclusion:Hengdian Jewelry Company's successful acquisition of the EPR certificate in Germany and France underscores our commitment to offering high-quality, eco-friendly gold-plated brass jewelry with zircon inlay to the global market. If you're in search of a reliable partner for jewelry wholesale, we not only offer an extensive range of designs but also ensure ethical and sustainable production.

-

-

-

-

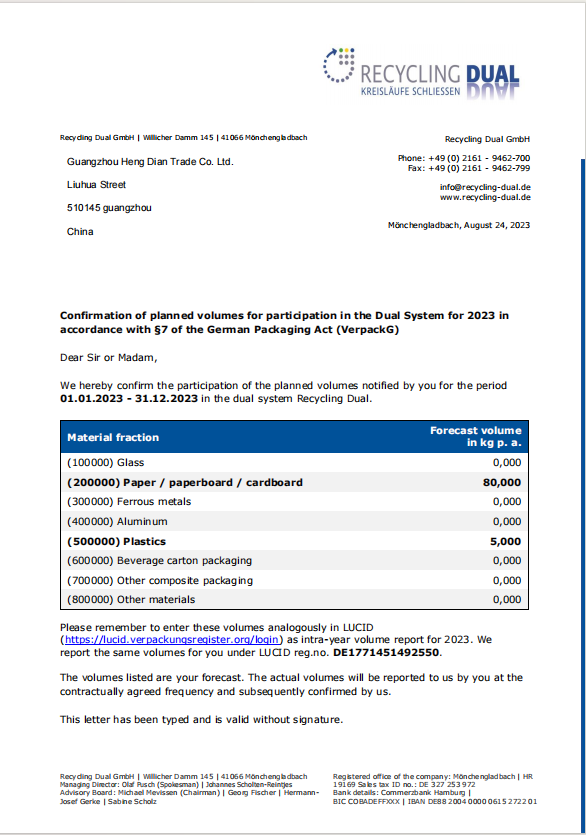

German epr certificate

Certificate No : DE1771451492550

Issuing authority : Recycling Dual GmbH

Valid period : 2023/1/1 - 2023/12/31

"Hengdian Jewelry's Eco-Friendly Journey: EPR Certification in Germany and France"

Introduction:Hengdian Jewelry Company takes immense pride in announcing its successful application for the EPR (Extended Producer Responsibility) certificate, a recognition of our unwavering commitment to sustainability. This article will elaborate on the value and validity of the EPR certificate in both Germany and France, while also introducing you to our core expertise: wholesale of exquisite fashion jewelry crafted from responsibly sourced gold-plated brass with zircon inlay. We extend a warm invitation to countries worldwide to explore mutually beneficial jewelry wholesale partnerships with us.Understanding the Significance of EPR Certification1. Germany: A Paradigm of Environmental ResponsibilityIn Germany, the EPR certificate is emblematic of a company's dedication to upholding stringent environmental standards. It underscores our promise to reduce waste, promote recycling, and minimize the environmental footprint of our jewelry production. By securing the EPR certification in Germany, Hengdian Jewelry Company is aligning itself with the eco-conscious principles that Germany holds dear, emphasizing the importance of environmentally responsible practices.2. France: Where Elegance Meets Environmental ResponsibilityIn France, the EPR certificate is a symbol of both fashion and eco-consciousness. It reflects a brand's commitment to producing exquisite jewelry while adhering to the highest environmental standards. By obtaining the EPR certificate in France, Hengdian Jewelry Company positions itself as a trusted source of jewelry that harmoniously combines sophistication and environmental responsibility, catering to the discerning French market.Hengdian Jewelry: Your Premier Destination for Sustainable Fashion JewelryHengdian Jewelry Company is a global leader in the wholesale of fashionable jewelry created from responsibly sourced gold-plated brass with exquisite zircon inlay. Our attainment of EPR certificates in Germany and France underscores our commitment to offering eco-friendly jewelry of the highest quality. Here's why we are the ideal partner for your gold-plated jewelry wholesale needs:1. Artistry at its Best:Our skilled artisans blend traditional craftsmanship with modern design sensibilities, ensuring each piece exemplifies the highest quality standards.2. Responsible Sourcing:We recognize the importance of eco-conscious jewelry production. Our gold-plated brass is responsibly sourced, and our zircon inlays are ethically procured, emphasizing our dedication to sustainability.3. A Vast Array of Designs:Our collection boasts an extensive range of designs to cater to diverse preferences. From timeless classics to contemporary trends, we offer a selection that appeals to a global clientele.4. Competitive Wholesale Prices:We provide competitive pricing for our wholesale partners, empowering your business to thrive while delivering top-quality jewelry to your customers.5. Global Wholesale Collaboration:Hengdian Jewelry Company warmly welcomes partners from around the world to engage in jewelry wholesale collaboration. With our EPR certificates in Germany and France, we are equipped to serve the international market while upholding the highest standards of quality and environmental responsibility.Conclusion:Hengdian Jewelry Company's successful acquisition of the EPR certificate in Germany and France underscores our commitment to offering high-quality, eco-friendly gold-plated brass jewelry with zircon inlay to the global market. If you're seeking a dependable partner for jewelry wholesale, we not only offer a wide array of designs but also assure ethical and sustainable production. Collaborate with us, and you'll discover a world of exquisite jewelry that meets the highest standards of quality and environmental responsibility.

-